The Full Guide to Membrane Switch Technology and Its Applications

The Full Guide to Membrane Switch Technology and Its Applications

Blog Article

Exactly How Membrane Layer Switches Contribute to the Toughness of Electronic Control Panels

Membrane switches play a crucial function in boosting the durability of digital control panels, mostly with their multi-layered construction which provides effective security against environmental factors such as dampness and dirt. The absence of relocating parts significantly minimizes the probability of mechanical failures, making membrane layer switches over suitable for requiring applications.

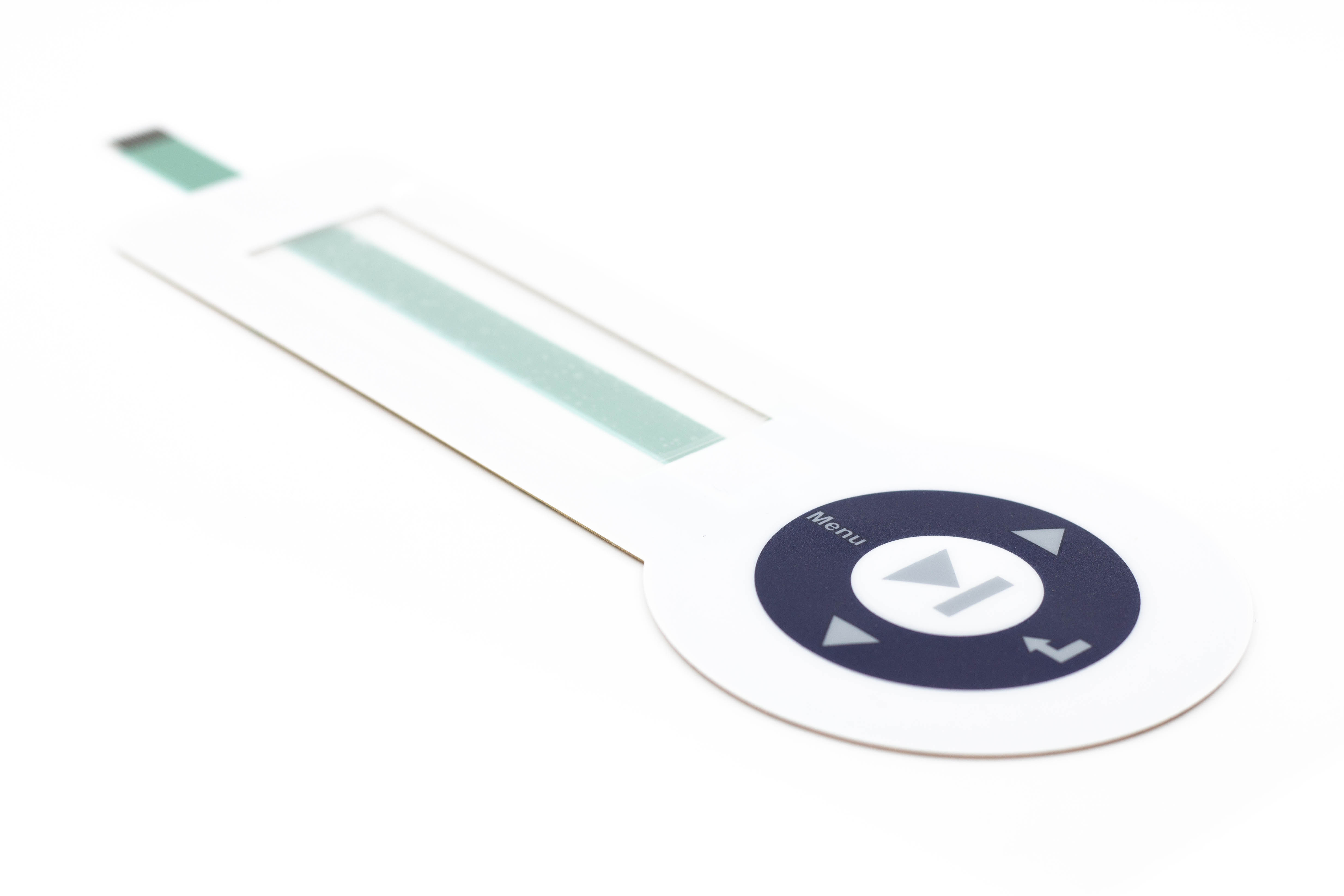

Meaning of Membrane Layer Switches

Membrane buttons are designed to be thin and lightweight, making them ideal for applications where area is restricted. They can be produced in numerous forms, dimensions, and colors, using versatility in layout that satisfies aesthetic and functional needs. Furthermore, membrane layer buttons can incorporate numerous innovations, such as tactile responses and LED signs, boosting customer experience.

Due to their building, membrane layer switches are often immune to dust, wetness, and general wear, adding to their longevity in demanding atmospheres. Their seamless style not only assists in very easy cleansing yet additionally minimizes the risk of mechanical failing, making them a preferred option for manufacturers looking for reliable customer interfaces in their digital control panels.

Protection Versus Ecological Factors

The layout of membrane layer switches over inherently gives a level of security against different ecological factors, which is crucial for preserving functionality in tough problems - Membrane Switch. These switches are generally built with layers of flexible products that protect interior components from dampness, dirt, and pollutants. By enveloping the wiring, membrane changes minimize the danger of short circuits and deterioration, which can dramatically hinder performance

Moreover, using robust adhesives and sealers during manufacturing boosts their resistance to environmental challenges. Membrane switches can withstand direct exposure to chemicals and solvents, making them ideal for industries such as food processing and healthcare, where hygiene and tidiness are vital. Their seamless surface layout likewise prevents the build-up of dust and germs, helping with less complicated cleaning and upkeep.

Temperature fluctuations are one more ecological issue, and membrane layer switches are engineered to operate effectively across a wide variety of temperatures (Membrane Switch). This flexibility guarantees that control panels stay operational in numerous settings, from industrial atmospheres to customer electronics

Influence on Customer Interaction

User communication with digital control panels is substantially affected by the design and functionality of membrane switches. see These buttons offer a responsive user interface that enhances the overall individual experience, enabling for instinctive navigation and control. Their receptive nature ensures that users get prompt responses upon activation, which is vital for jobs requiring accuracy and efficiency.

Furthermore, the smooth surface of membrane changes assists in very easy cleansing and upkeep, advertising individual self-confidence in the dependability of the user interface. This tidiness is especially crucial in settings where health is critical, such as medical read this post here or food processing settings. In addition, the portable and light-weight layout of membrane layer switches over adds to the visual appeal of control panels, motivating user involvement through a contemporary and smooth appearance.

Additionally, the integration of visual elements, such as published symbols and backlighting, assists users quickly recognize features, lowering the discovering curve associated with brand-new devices. Consequently, users can operate tools a lot more efficiently, leading to increased performance and complete satisfaction. In recap, membrane buttons play a pivotal role in enhancing user communication by integrating capability, appearances, and convenience of use, ultimately bring about enhanced functional effectiveness.

Style Flexibility and Modification

Style adaptability and personalization are essential elements of membrane buttons, enabling makers to tailor electronic control board to certain applications and user demands. This adaptability permits for the integration of different layout aspects, such as shades, graphics, and textures, which can improve the aesthetic charm and customer engagement of the control panel.

Membrane buttons can be personalized in shapes and size, accommodating a variety of devices and applications, from industrial equipment to customer electronics. This flexibility ensures that producers can develop instinctive interfaces that align with customer assumptions and operational demands. Furthermore, the capacity to include unique features such as backlighting or responsive responses additionally improves usability, permitting a more interactive experience.

In addition, the production procedure for membrane layer changes sustains the rapid prototyping of styles, allowing makers to repeat and improve their principles promptly. This capability not only speeds up the advancement timeline yet additionally makes certain that the end product satisfies particular practical and aesthetic standards.

Cost-Effectiveness and Durability

Cost-effectiveness and durability are considerable benefits of membrane layer buttons, making them an appealing option for manufacturers and end-users alike. These buttons are commonly more economical to create than conventional mechanical switches, mainly due to their simplified production processes and the reduced variety of parts called for. This expense advantage expands not only to initial manufacturing however likewise to long-term functional costs, as membrane buttons typically require less maintenance and have a reduced failure price.

Additionally, the about his longevity of membrane layer changes contributes to their total value. Created from long lasting materials, they are immune to environmental factors such as dampness, dust, and chemicals, which can lead to early wear in other switch types. The lack of relocating parts lessens mechanical failure, allowing membrane layer switches to preserve functionality over expanded periods.

This resilience is specifically valuable in applications requiring regular performance under demanding problems, such as medical tools and industrial tools. Ultimately, the mix of cost-effectiveness and longevity makes membrane switches over a financially practical option for manufacturers, giving trustworthy remedies that withstand the test of time while enhancing budgetary factors to consider.

Conclusion

In verdict, membrane buttons dramatically boost the durability of digital control panels via their durable construction and safety attributes - Membrane Switch. Generally, membrane layer changes represent a reliable and cost-efficient option for improving the durability and functionality of digital control systems.

Report this page